Guest

Guest

Sep 09, 2025

7:22 AM

|

Trailer Component Manufacturing: Embracing Technology and Industry 4.0

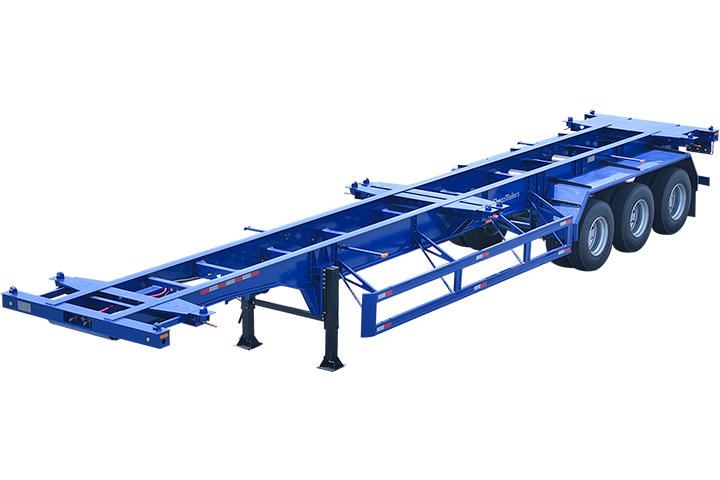

The trailer industry is evolving rapidly as technology transforms the way components are designed and produced. Today, trailer component manufacturing is no longer limited to traditional fabrication—it is becoming a high-tech sector powered by automation, digitalization, and Industry 4.0 innovations.

Xem Chi Tiet Bai Viet Tai: trailer component manufacturing?

Automation in Manufacturing

Automation has reshaped how critical trailer components such as axles, chassis frames, and braking systems are produced. Robotic welding ensures consistency, while CNC laser cutting delivers precision in steel processing. Automated assembly lines also reduce human error and speed up production, allowing manufacturers to meet growing global demand.

Tham Khao: Precision in Every Component

For trailer component manufacturing, automation means higher efficiency, safer working environments, and better quality assurance.

Tham Khao: Trailer Component Manufacturing: Global Opportunities in Mechanical Engineering & Supporting Industries

Digital Twins and Simulation

Industry 4.0 introduces powerful tools like digital twins, enabling engineers to simulate trailer components under real-world stress conditions. By modeling load distribution, vibration, and fatigue, manufacturers can optimize designs before physical prototypes are built. This reduces costs, accelerates development, and improves reliability.

Tham Khao Them Tai: Trailer Component Manufacturing: Global Opportunities in Mechanical Engineering & Supporting Industries

IoT and Smart Components

Modern trailers increasingly rely on smart technologies. Sensors embedded in axles, suspensions, and braking systems provide real-time data on wear, load capacity, and temperature. Through the Internet of Things (IoT), these smart components improve fleet safety and efficiency.

Manufacturers specializing in trailer component manufacturing who integrate IoT into their products gain a competitive advantage in meeting the needs of advanced logistics providers.

Data-Driven Production

Big data and AI are transforming factory operations. With predictive analytics, manufacturers can forecast component demand, optimize supply chains, and schedule maintenance for equipment before breakdowns occur. This not only reduces downtime but also enhances responsiveness to customer needs.

Sustainability and Green Engineering

Technology also supports sustainability in trailer component production. Automated cutting reduces material waste, while advanced coatings extend component life and reduce environmental impact. Lightweight materials, such as aluminum and composites, are increasingly used to lower trailer weight, improving fuel efficiency and reducing CO? emissions.

Workforce Transformation

As automation grows, so does the need for highly skilled engineers and technicians. Workers trained in robotics, AI, and data analysis are essential for operating modern factories. Manufacturers investing in training and education strengthen their long-term competitiveness in the global trailer industry.

Conclusion

Trailer component manufacturing is undergoing a technological revolution driven by automation, digital twins, IoT, and Industry 4.0. These innovations enhance efficiency, sustainability, and product reliability while opening new opportunities in global markets.

By embracing advanced technology, manufacturers are not only improving production but also reshaping the future of mechanical engineering and supporting industries—ensuring trailers remain safe, efficient, and sustainable in a fast-changing world. Thaco Industries consistently applies advanced technologies to ensure that all products meet international standards. Thanks to its systematic investments, the company has become a trusted OEM partner for many global corporations across key industrial sectors.

#trailer_component_manufacturing?, #trailercomponentmanufacturing?, #Thaco_Industries, #ThacoIndustries, #Thaco_Industries

|